In the modern manufacturing landscape, precision is the cornerstone of success. From aerospace and automotive to medical devices and general engineering, industries demand components that meet exacting standards. Thread turning is one of the most critical machining processes, and high-precision thread turning tools play an indispensable role in achieving superior results.

This blog explores the advantages of using high-precision thread turning tools, focusing on their impact on quality, productivity, and cost-efficiency. We will also highlight Samtec Tools, a trusted provider of innovative cutting tool solutions, for those seeking reliable and high-quality thread turning tools.

What is Thread Turning?

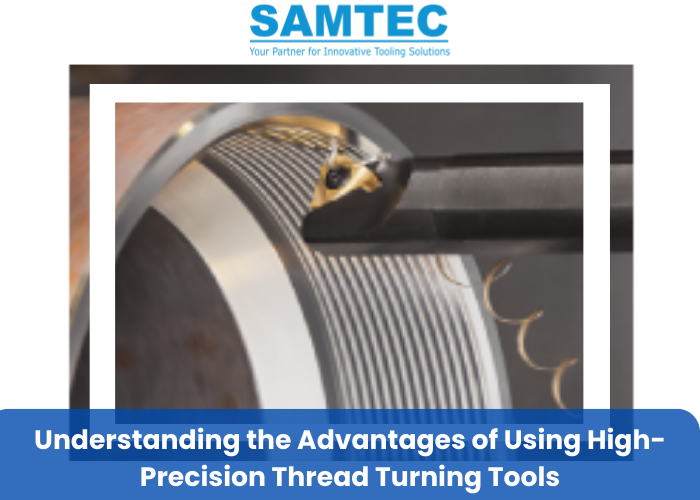

Thread turning is a machining process where threads are cut into a cylindrical or conical workpiece using a lathe. The resulting threads may be external (e.g., bolts) or internal (e.g., nuts). Thread turning is widely used in various industries to create threaded components essential for fastening, sealing, or transmitting motion.

High-precision thread turning tools are specifically designed to achieve exceptional accuracy and consistency in thread production. These tools address challenges such as maintaining thread tolerances, achieving surface finish requirements, and optimizing machining times.

Key Advantages of High-Precision Thread Turning Tools

- Superior Thread Quality

High-precision tools are engineered to deliver excellent thread quality, including accurate dimensions, tight tolerances, and smooth finishes. The precision of these tools ensures that threads align perfectly with mating components, reducing the risk of failure during operation.

-

- Example: In aerospace applications, where threaded components must withstand extreme stresses, high-precision tools ensure reliability and durability.

- Enhanced Productivity

With high-precision thread turning tools, machining times are significantly reduced. These tools allow for higher cutting speeds, deeper cuts, and optimized feed rates without compromising quality.

-

- Result: Faster production cycles lead to increased throughput, which is vital for industries handling large-scale manufacturing projects.

- Extended Tool Life

The use of high-quality materials and advanced coatings in precision tools enhances their durability. This reduces wear and tear, allowing the tools to maintain their cutting edge for longer periods.

-

- Benefit: Longer tool life minimizes downtime for tool changes, thereby increasing overall efficiency.

- Versatility

High-precision thread turning tools can handle a wide variety of materials, including steel, aluminum, titanium, and exotic alloys. This versatility makes them suitable for diverse industrial applications.

-

- Industries Served: Automotive, oil and gas, aerospace, medical devices, and more.

- Cost-Effectiveness

Although high-precision tools may have a higher initial cost, their long-term benefits outweigh the investment. Reduced scrap rates, lower tool replacement frequency, and increased productivity translate into significant cost savings.

-

- Example: Precision tools ensure consistent thread quality, eliminating costly rework and material wastage.

- Improved Safety

Precision tools reduce the likelihood of machining errors, which can compromise component integrity and pose safety risks. By delivering accurate and reliable results, these tools contribute to safer operations across industries.

Technological Innovations in High-Precision Thread Turning Tools

Modern thread turning tools incorporate advanced technologies to meet the evolving demands of manufacturers. Here are some noteworthy innovations:

- Indexable Inserts

High-precision thread turning tools often feature indexable inserts, which can be replaced without changing the entire tool. These inserts are made from materials like carbide or ceramic and coated with substances such as TiN or AlTiN for enhanced performance.

-

- Advantages:

- Cost-efficient replacement

- Consistent cutting performance

- Quick tool changes

- Advantages:

- Multi-Start Threading

Multi-start threading tools enable the production of threads with multiple starts, which are commonly used in high-load or high-speed applications. These tools simplify the process, ensuring precision and efficiency.

- CNC Compatibility

High-precision thread turning tools are designed for use with CNC machines, offering automated and highly accurate thread production. CNC compatibility allows for complex threading geometries and customization.

- Advanced Coatings

Modern coatings enhance tool performance by:

- Reducing friction and heat generation

- Increasing wear resistance

- Improving surface finishes

- Common Coatings:

- Titanium Nitride (TiN)

- Titanium Aluminum Nitride (TiAlN)

- Diamond-like Carbon (DLC)

Why Choose Samtec Tools for High-Precision Thread Turning Tools?

When it comes to high-precision thread turning tools, Samtec Tools stands out as a reliable and innovative provider. Here’s why:

- Wide Range of Products

Samtec Tools offers a comprehensive range of thread turning tools, including indexable inserts, carbide tools, and custom solutions. Their products cater to various industries and applications.

- Commitment to Quality

Samtec Tools prioritizes quality and precision in their manufacturing processes. Their tools are designed to meet the highest standards, ensuring reliable performance and longevity.

- Customization Options

Samtec Tools provides tailored solutions to meet specific customer requirements. Whether you need tools for unique thread profiles or challenging materials, their team can deliver.

- Expert Support

With years of expertise in cutting tools, Samtec Tools offers exceptional customer support. Their team provides guidance on tool selection, usage, and optimization to ensure you achieve the best results.

- Competitive Pricing

Samtec Tools combines high quality with affordability, making their products a cost-effective choice for manufacturers.

Applications of High-Precision Thread Turning Tools

- Aerospace Industry

Threaded components in aerospace applications demand extreme precision to ensure safety and performance. High-precision tools are essential for producing these components to exacting standards.

- Automotive Industry

From engine parts to suspension systems, threaded components are integral to automotive manufacturing. Precision tools enable fast and accurate production, meeting the industry’s high-volume demands.

- Oil and Gas Sector

Threads used in drilling and pipeline components must withstand harsh environments. High-precision tools ensure durability and reliability in these critical applications.

- Medical Devices

Precision is paramount in medical devices, where threads must meet stringent standards for safety and compatibility. High-precision tools enable the production of flawless components.

Choosing the Right Thread Turning Tools

Selecting the right thread turning tools involves considering factors such as:

- Material of the Workpiece: Choose tools compatible with the material to optimize performance.

- Thread Type and Profile: Ensure the tool can produce the required thread geometry.

- Machining Environment: Consider factors like cutting speeds, coolant usage, and machine compatibility.

- Cost and Longevity: Evaluate the tool’s cost relative to its expected lifespan and performance.

For personalized recommendations, consult experts like Samtec Tools, who can help you choose the ideal tools for your needs.

Conclusion

High-precision thread turning tools are essential for industries requiring accuracy, consistency, and efficiency in thread production. Their advantages include superior thread quality, enhanced productivity, extended tool life, versatility, cost-effectiveness, and improved safety. By investing in advanced tools, manufacturers can achieve higher standards and maintain a competitive edge.

Samtec Tools is a trusted partner for high-precision thread turning tools. With their commitment to quality, innovation, and customer satisfaction, they are an excellent choice for manufacturers seeking reliable and efficient solutions.

Elevate your machining processes with high-precision thread turning tools from Samtec Tools and experience the difference in quality and performance.